Enhancing Paper Production Efficiency: Synthetic Polyester SSB Triple Forming Fabric

2023-10-17

Introduction:

In the paper manufacturing industry, optimizing the production process while maintaining high-quality paper is a constant goal. Synthetic Polyester SSB Triple Forming Fabric is an innovative technology that revolutionizes the paper forming process, improving efficiency and enhancing the overall quality of paper products. In this blog, we will delve into the features, benefits, and applications of Synthetic Polyester SSB Triple Forming Fabric, shedding light on how it transforms the paper manufacturing industry.

Understanding Synthetic Polyester SSB Triple Forming Fabric:

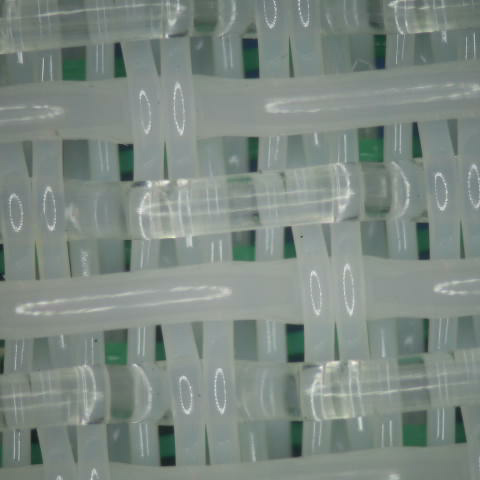

Synthetic Polyester SSB Triple Forming Fabric refers to a specialized fabric used in the paper forming section of paper machines. It plays a critical role in the formation and dewatering of paper, facilitating the removal of water while promoting uniform fiber distribution. This fabric is made from synthetic polyester materials, designed to withstand the demanding conditions of the papermaking process.

Features and Functionality:

1. Triple Layer Design: Synthetic Polyester SSB Triple Forming Fabric consists of three distinct layers: a top wear-resistant layer, a middle support layer, and a bottom drainage layer. Each layer serves a specific function to optimize the paper forming process.

2. Enhanced Drainage and Fiber Retention: The bottom drainage layer of Synthetic Polyester SSB Triple Forming Fabric allows for efficient water drainage, reducing water content in the forming paper. Simultaneously, it retains fibers within the fabric, preventing fiber loss during the dewatering process. This feature contributes to the production of high-quality paper with uniform fiber distribution.

3. Increased Sheet Stability: The middle support layer of Synthetic Polyester SSB Triple Forming Fabric provides stability to the sheet as it forms. It aids in controlling sheet shrinkage and reducing web flutter, resulting in improved paper formation and increased production speeds.

4. Wear-Resistant Surface: The top layer of Synthetic Polyester SSB Triple Forming Fabric is engineered with excellent wear resistance. This characteristic allows the fabric to withstand the continuous abrasion caused by the movement of paper fibers and machine components, ensuring prolonged service life and reduced downtime for fabric replacement.

Benefits of Synthetic Polyester SSB Triple Forming Fabric:

1. Enhanced Paper Formation: The specialized design of Synthetic Polyester SSB Triple Forming Fabric promotes consistent fiber distribution, resulting in improved paper formation. The fabric's ability to retain fibers and optimize drainage contributes to the production of paper with better strength, uniformity, and printability.

2. Increased Machine Efficiency: By optimizing water drainage and improving fiber retention, Synthetic Polyester SSB Triple Forming Fabric enhances machine efficiency and productivity. The fabric enables faster dewatering, reducing drying time and energy consumption. Increased machine efficiency translates to higher production rates and cost savings.

3. Extended Fabric Lifespan: The wear-resistant surface of Synthetic Polyester SSB Triple Forming Fabric ensures longevity and durability. It withstands the constant wear and abrasion of the papermaking process, reducing fabric replacement frequency and associated maintenance costs. This extended lifespan leads to improved operational efficiency and reduced downtime.

4. Versatile Applications: Synthetic Polyester SSB Triple Forming Fabric is suitable for a wide range of paper grades and machine configurations. Whether it's printing and writing papers, packaging materials, or specialty papers, this fabric can adapt to various paper manufacturing processes, providing consistent and reliable performance.

Applications of Synthetic Polyester SSB Triple Forming Fabric:

Synthetic Polyester SSB Triple Forming Fabric finds applications in numerous paper manufacturing processes, including:

1. Fine Paper Production: The high-quality paper formation facilitated by Synthetic Polyester SSB Triple Forming Fabric makes it ideal for fine paper production. This includes printing and writing papers, where surface smoothness, uniformity, and printability are critical.

2. Packaging and Board Production: The fabric's ability to optimize drainage and fiber retention lends itself well to the production of packaging materials and boards. The consistent formation and strength provided by Synthetic Polyester SSB Triple Forming Fabric contribute to the production of robust and reliable packaging products.

3. Specialty Paper Manufacturing: Synthetic Polyester SSB Triple Forming Fabric is also used in the production of specialty papers, such as tissue, decor papers, and specialty packaging. The fabric's versatility and ability to adapt to different paper grades make it suitable for achieving the unique characteristics required by specialty paper products.

Conclusion:

Synthetic Polyester SSB Triple Forming Fabric is a game-changer in the paper manufacturing industry, enhancing efficiency, quality, and overall productivity. Its triple layer design, optimized drainage, fiber retention capabilities, and wear-resistant surface contribute to improved paper formation, increased machine efficiency, and extended fabric lifespan. With its versatility and adaptability to various paper grades, Synthetic Polyester SSB Triple Forming Fabric sets new standards for high-quality paper production, offering manufacturers the means to optimize their processes and deliver superior paper products to meet market demands.